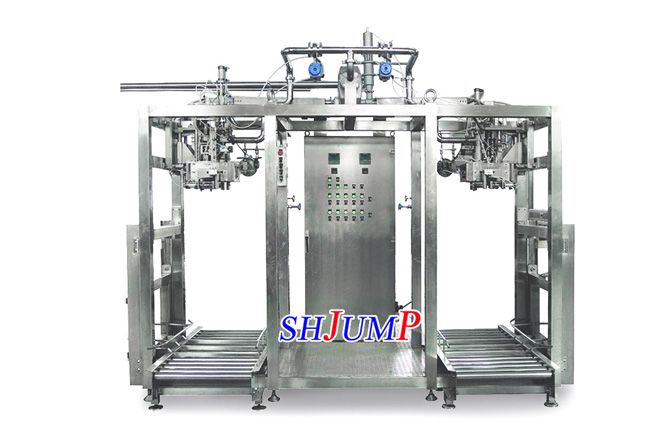

Aseptic sack filler is mainly composed of aseptic filling head, operating system, man-machine control system, steam system, measuring system and workbench and so on, with independent control cabinet and simple button box, touch screen and programmable controller (PLC) USES Germany Siemens, solenoid valve and cylinder, a guest is used, use schneider switch button; The measuring system adopts siniere electromagnetic flowmeter and aluminum-plastic compound aseptic bag (5L-220L).

Aseptic bag filling machine sterilizes the bag opening and filling chamber using steam injection method to ensure that the filling chamber is always in aseptic state. Aseptic bag opening sterilization, filling and sealing are completed in aseptic environment. Double the filler filling head switching are two filling, filling material zero reflux (such as first in filling at the same time, the two do bag, bag after the completion of the injection steam sterilization on the bag mouth, for the first filling end, aseptic filling valve switch to the first two), with CIP cleaning equipment, SIP sterilizing process, can realize with the front end of the sterilization machine, No need for separate cleaning and sterilization.

|

产品型号 |

JP-WJGZ-1 |

JP-WJGZ-2 |

JP-WJGZ-3 |

JP-WJGZ-6 |

JP-WJGZ-8 |

JP-WJGZ-10 |

JP-WJGZ-12 |

|

灌装能力 |

1000 kg/h |

2000 kg/h |

3000 kg/h |

6000 kg/h |

8000 kg/h |

10000 kg/h |

12000 kg/h |

|

灌装头数 |

1 |

1 |

1 |

2 |

2 |

2 |

2 |

|

设备功率 |

4.5 kw |

4.5 kw |

4.5 kw |

7.5 kw |

7.5 kw |

7.5 kw |

7.5 kw |

|

蒸汽耗量 |

100 kg /h |

100 kg /h |

100 kg /h |

200 kg /h |

200 kg /h |

200 kg /h |

200 kg /h |

|

压缩空气 |

0.3 kg/h |

0.3 kg/h |

0.3 kg/h |

0.6 kg/h |

0.6 kg/h |

0.6 kg/h |

0.6 kg/h |

|

设备尺寸 |

2700*1800*2800mm |

2700*1800*2800mm |

2700*1800*2800mm |

4200*1800*2800mm |

4200*1800*2800mm |

4200*1800*2800mm |

4200*1800*2800mm |